Semiconductor tape reels have undergone significant technological advancements to meet the evolving needs of the electronics industry. These innovations have enhanced the performance, reliability, and versatility of tape reel packaging for semiconductor components. In this article, we will explore some of the latest developments in semiconductor tape reel technology.

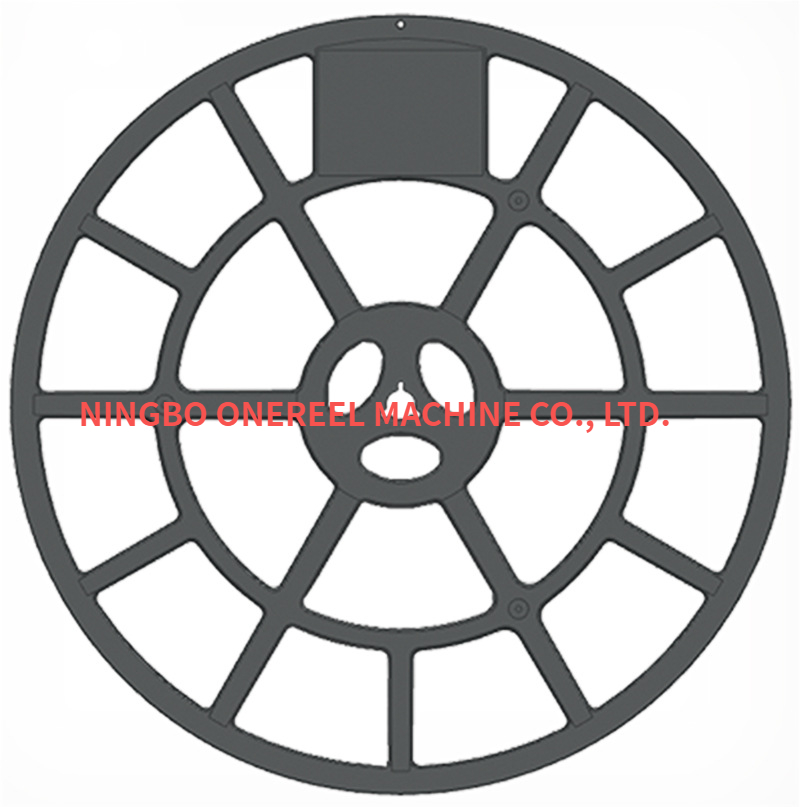

1. Enhanced Material Selection: Modern semiconductor tape reels utilize advanced materials that offer improved durability, ESD protection, and environmental sustainability. High-performance plastics and conductive polymers are increasingly being employed to manufacture tape reels with superior mechanical strength and static dissipation properties. These materials help safeguard semiconductor components against electrostatic discharge and ensure their integrity throughout the supply chain.

2. Miniaturization and High-Density Packaging: With the demand for smaller and more densely packed electronic devices, semiconductor tape reels have adapted to accommodate miniature and ultra-miniature components. Miniaturized tape reels feature narrower tape widths and smaller pocket pitches, enabling the efficient packaging of microchips, microcontrollers, and other compact semiconductor devices. This trend towards high-density packaging enhances PCB design flexibility and enables the realization of sleeker, more compact electronic products.

3. Intelligent Reel Management Systems: Semiconductor tape reel manufacturers are integrating intelligent reel management systems into their products to streamline inventory management and traceability. These systems utilize RFID tags, barcode labels, or NFC technology to provide real-time tracking and monitoring of reel inventory throughout the manufacturing process. By digitizing reel data and automating inventory control, semiconductor manufacturers can optimize production efficiency, reduce errors, and ensure compliance with industry regulations.

4. Eco-Friendly Initiatives: In response to growing environmental concerns, semiconductor tape reel manufacturers are implementing eco-friendly initiatives to reduce the ecological footprint of their products. This includes the use of recyclable materials in reel construction, as well as the adoption of energy-efficient manufacturing processes. Furthermore, some companies offer take-back programs for used tape reels, promoting closed-loop recycling and sustainable resource management within the electronics industry.

5. Integration with Industry 4.0: As part of the Industry 4.0 revolution, semiconductor tape reel technology is becoming increasingly interconnected and digitally enabled. Smart tape reels equipped with IoT sensors and wireless connectivity allow for seamless integration with smart factories and automated assembly systems. By harnessing real-time data analytics and predictive maintenance algorithms, manufacturers can optimize reel usage, prevent production delays, and improve overall equipment effectiveness (OEE).

In conclusion, advancements in semiconductor tape reel technology are driving innovation and efficiency in the electronics industry. From enhanced material properties to intelligent reel management systems, these developments are shaping the future of semiconductor packaging and enabling the production of next-generation electronic devices.